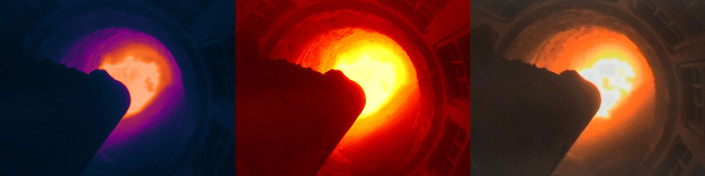

Even though rotary kilns have been used for decades, monitoring its burner remains a challenge, even more so at a time when energy sustainability is so important. Because of standard fuel restrictions, the use of alternative fuels is constantly increasing, thus making control of the flame pattern, size and temperature crucial.

Some parts of the cement clinker’s production process are not always well monitored, such as with the kiln burner flame and the coolers. Providing reliable temperature reading inside the kiln at the burner side, even in a dusty environment, is not an easy task and requires high-end reliable tools.

Pyroscan is a pyrometric camera displaying high quality images with much more detail in both the dark and bright areas thanks to the full High Dynamic Range (HDR) thermal images. With an unlimited number of user-defined measurements points, it provides reliable temperature readings, even in a dusty environment. Pyroscan enables the visualization of temperature measurements in the clinker area and flame shape monitoring with user-defined analysis lines.

In addition, it can monitor the avalanches and red rivers inside the grate cooler.

HGH is a electro-optical devices global provider. The company provides wide area surveillance, industrial thermography and electro-optical test solutions.